Appliance testing and tagging

At LGE Electrical Services, we prioritise the safety and reliability of your electrical equipment. Our appliance testing and tagging service is an essential part of maintaining a safe workplace, ensuring that all portable appliances comply with Australian safety standards set by the AS/NZS 3760 standard. With our experienced team and comprehensive testing processes, we provide peace of mind that your equipment is safe to use and meets all regulatory requirements.

Appliance testing and tagging is a systematic procedure used to evaluate the electrical safety of portable appliances and equipment. This process involves inspecting, testing, and tagging electrical appliances to ensure they are safe for use in commercial and industrial environments. Testing and tagging appliances is vital for preventing electrical hazards, such as shocks, fires, and equipment damage, that can occur due to faulty or damaged appliances.

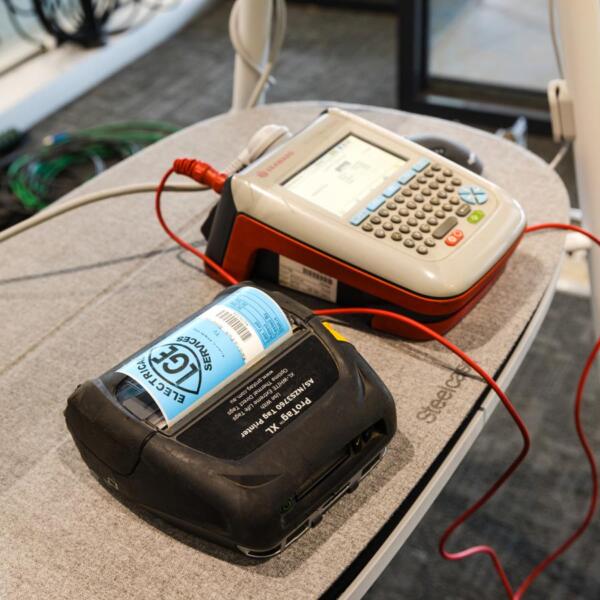

At LGE Electrical Services, we use the Seaward Elite Plus tester, renowned as one of the most reputable and best-performing devices on the market. To maintain the highest standards our advanced tester is calibrated annually to ensure accurate and reliable results, contributing to the safety of your workplace and maintaining that our testing procedures remain precise and compliant with industry regulations.

Our team at LGE Electrical Services can assist you in determining the appropriate testing schedule for your specific appliance in accordance with the AS/NZS 3760 Australian Standard. The frequency of testing depends on the environment in which the appliances are used. Frequently moved appliances must be tested and tagged more often than stationary appliances that are not moved frequently. Appliances in manufacturing spaces must undergo testing every six months. Hire service equipment and portable tools used on construction sites need to be tested every three months to maintain compliance and safety. Appliances in accommodation spaces also have different testing periods.

Key services

Visual inspection

- Physical condition assessment: Our technicians conduct a thorough visual inspection of the appliance to check for any visible signs of damage, such as frayed cords, broken plugs, or exposed wiring.

- Label and rating check: We review that each appliance is properly labelled with its electrical rating and that all warning labels are intact and legible.

Electrical testing

- Earth continuity test: This test verifies that the appliance is properly grounded.

- Insulation resistance test: We measure the insulation resistance to detect any potential leakage current that could lead to shocks or short circuits.

- Polarity check: This test ensures that the wiring connections are correct and that plugs or cords do not have reverse connections.

Tagging and documentation

- Tagging: Each tested appliance is tagged with a durable label indicating its status (pass or fail), the date of testing, and the next scheduled test date.

- Reporting: We provide reports of all tests conducted, essential for compliance audits and future reference.